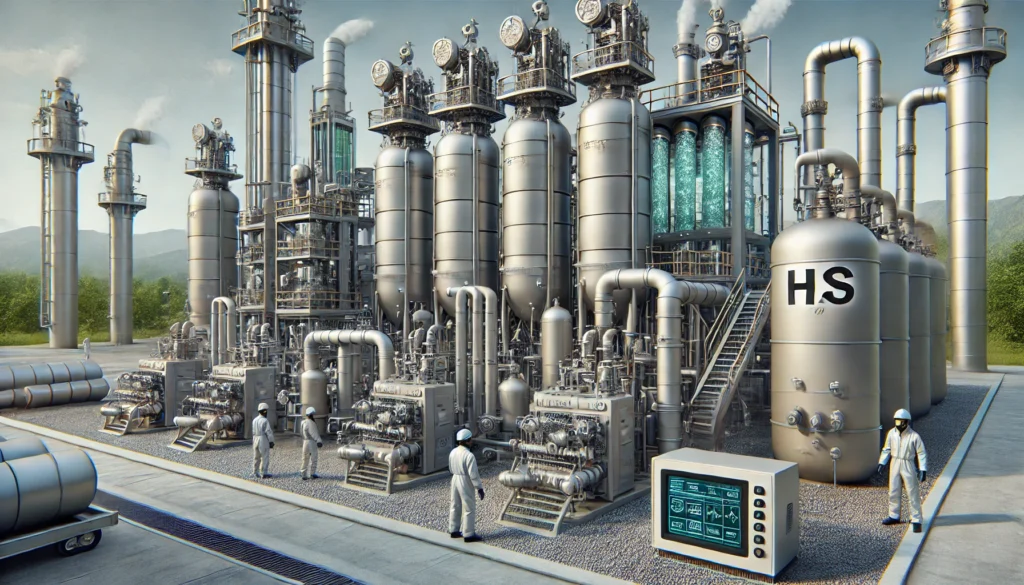

H2S Removal

H2S removal is essential in crude oil and natural gas production, as well as in wastewater treatment, utility facilities, and sewers. Specifically, H2S is produced by the microbial breakdown of organic materials in oxygen-free environments. This colorless, flammable, and corrosive gas is notorious for its rotten egg smell. Additionally, it has toxicity similar to carbon monoxide, blocking cellular respiration. Thus, early detection of H2S is critical to ensuring safety.

Since H2S is heavier than air, it tends to collect in low-lying, poorly ventilated spaces. In oil and gas applications, sour gas containing H2S can form sulfuric acid when exposed to air and moisture. As a result, this acid corrodes metals, which reduces the durability of facility equipment and internal surfaces.

Why Choose HAWK ENERGY?

HAWK ENERGY is a leader in cost-effective contaminant removal solutions for gaseous and light liquid hydrocarbon streams. Through our advanced fixed-bed technology, we target H2S removal efficiently. Our solutions include two primary product lines:

- Granular Iron-Oxide H2S Adsorbents: These are ideal for saturated gas streams.

- High-Capacity Mixed-Metal Oxide Adsorbents: These work effectively for both dry and saturated gas streams.

System Design

Each system is specifically tailored to match process-specific conditions. In gas treatment, the flow is directed downward through the bed, while for liquids, an upflow configuration is used. As H2S contaminants pass through, they chemically react with the adsorbent, creating a stable by-product. Consequently, this flexible design adapts to changing conditions without requiring additional equipment.

Comprehensive Support

Our comprehensive solutions range from basic media supply to full technical system design. This includes media provision, engineering, fabrication, equipment supply, and spent-media handling. Moreover, most systems utilize a Lead-Lag Configuration, which allows for greater flexibility and media optimization. As gas flows through the lead and lag beds, each bed’s full capacity is maximized, boosting removal efficiency by up to 20%.

When the lead bed becomes spent, it is taken offline for replacement, while the lag bed remains operational. After refilling, the beds are rotated, ensuring optimal absorbent use. Product consumption is directly proportional to the amount of H2S treated, which guarantees efficiency and cost-effectiveness.

Quality and Precision

Our products meet stringent quality standards. Additionally, with custom software modeling and performance predictability, we can support best-fit system designs and optimized operation for each application, guided by our skilled personnel at every stage.

ADVANTAGES:

Reliable, predictable performance

Customized, flexible purification system

Wide range of adsorbents providing optimized solutions

Responsive and Respectful

Cost-effective hydrogen sulfide removal

Straightforward vessel changeouts

Mobile removal units

Highly qualified, trained, and experienced support network

Hawk Energy offers dedicated adsorbent for the removal of H2S from water and liquid hydrocarbon streams.